Fire Safety Equipment has extensive experience in the design, engineering calculations, and implementation of gaseous flood systems. Below are a few examples of well-known projects in which FSE in addition to the design and supply of the fire suppression and fire prevention system, provided such services as design drawing, design verification, system hydraulic calculations, and room integrity testing/verification.

Contact FSE today to discuss your special hazards project. We are confident in finding the best and most cost-effective solution to meet your needs.

FirePro for Auckland's First 100% Electric Ferry

Location: Auckland, New Zealand

Sector: Marine / Public Transport

System: FirePro Condensed Aerosol Fire Suppression

Completed: 2025

Project Overview

As Auckland advances toward a cleaner and more sustainable future, EV Maritime’s fully electric ferry represents a groundbreaking step in low-emission transport. Purpose-built by McMullen & Wing, this innovative vessel carries up to 200 passengers between Half Moon Bay and Downtown Auckland – all without a drop of fossil fuel.

Our Role

Fire Safety Equipment was proud to support this landmark project by supplying and commissioning 11 FirePro fire suppression systems across multiple high-risk areas of the vessel. Special attention was given to the port and starboard battery rooms, where dual FirePro generators provide rapid-response, double-shot protection to help contain any potential battery-related fire incidents.

The Solution

The FirePro aerosol system was selected for its compact footprint, minimal maintenance requirements, and proven effectiveness in enclosed, high-energy environments like lithium battery compartments. With no need for complex pipework or high-pressure cylinders, FirePro was the ideal fit for the vessel’s advanced and space-sensitive engineering.

Outcome

This project marks a proud milestone for Fire Safety Equipment as Auckland’s largest city takes bold steps in its “Mission Electric” transport transition. The ferry now operates with reliable, modern fire suppression technology that safeguards both passengers and infrastructure.

Why It Matters

This isn’t just a case of protecting a vessel — it’s about future-proofing the infrastructure of tomorrow’s clean public transport. Fire Safety Equipment is committed to supporting projects that align with environmental goals while upholding the highest standards of fire protection.

CO₂ Fire Suppression for Major New Zealand Power Station

Client: Confidential (Power Generation Sector)

Location: New Zealand

Sector: Energy / Infrastructure

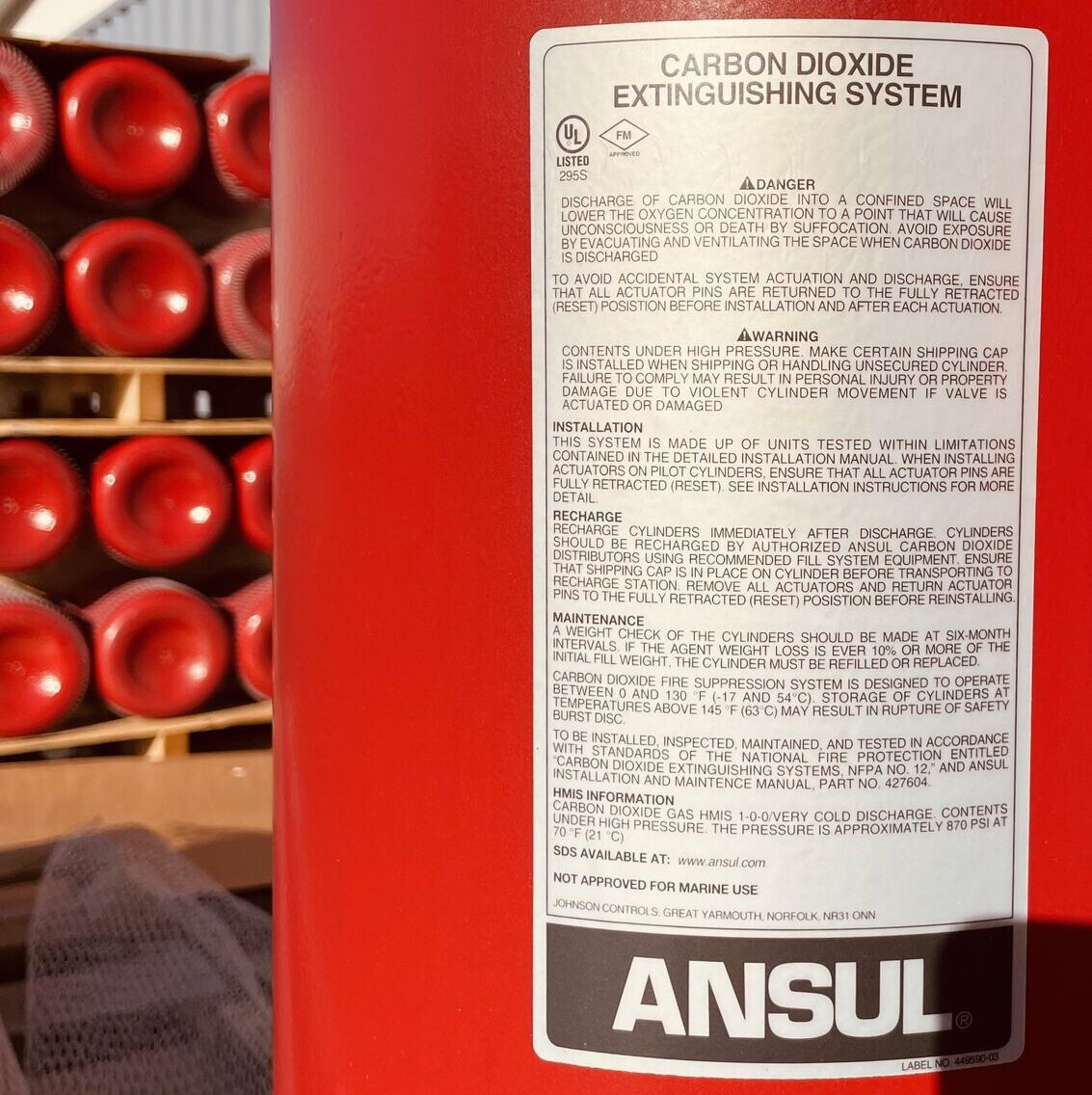

System: ANSUL High-Pressure CO₂ Fire Suppression

Scope: 147 x 100lb Cylinders

Completed: 2024

Project Overview

As part of a major upgrade to fire safety infrastructure at a large New Zealand power station, Fire Safety Equipment recently supplied a high-capacity CO₂ suppression system consisting of 147 ANSUL 100lb cylinders. These systems are designed to protect critical operational areas across the facility where flammable liquids, electrical equipment, or unoccupied enclosed spaces pose elevated fire risks.

Our Role

Fire Safety Equipment was engaged to provide a complete supply and logistics solution for this large-scale CO₂ system. Leveraging our strong relationship with ANSUL and extensive knowledge of gaseous suppression design, we ensured all components were sourced, prepared, and dispatched in accordance with exacting safety standards and tight project timelines.

The Solution

While high-pressure CO₂ systems are less commonly specified in modern designs due to safety considerations in occupied areas, they remain one of the most effective suppression solutions in environments where automatic, non-damaging, and cost-effective protection is required. In this case, the system will deliver fast, total flooding discharge to rapidly suppress fire threats in key risk zones.

Outcome

With all 147 cylinders now on their way to site, the project represents one of the largest single CO₂ deployments we’ve undertaken in recent years. The customer benefits from a proven, low-maintenance suppression solution delivered by a team with deep expertise in both traditional and next-generation technologies.

Why It Matters

Not every fire suppression challenge fits the same mould. This project highlights Fire Safety Equipment’s ability to deliver tailored solutions — whether based on modern condensed aerosol technology or tried-and-true classics like CO₂. When safety and reliability matter most, we’re the team to call.

Vessel – Ika Rere

Sea Trials: 2021

FirePro Protects Southern Hemisphere’s First Electric Ferry

In September 2021, Wellington Electric Boat Building Company (WEBBCo) entered the sea trials stage with the Southern Hemisphere’s first fully electric, high speed passenger ferry. The 19m carbon fibre-constructed catamaran for East by West Ferries will carry up to 135 passengers on their daily commute from Queens Wharf to Days Bay at an optimum service speed of 20 knots, charging between trips at the newly installed charging stations on the wharves.

This unprecedented ferry was the vision of Jeremy Ward, CEO of East by West Ferries, and Fraser Foote, Managing Director of WEBBCo, working in close collaboration with established NZ maritime experts in the fields of naval architecture and design, electrical systems, composites engineering and materials, and electrification consultants.

Fire Safety Equipment are proud to be the designers and suppliers behind the FirePro Fire Suppression system protecting various enclosures in this vessel including not only the electric motors but also the battery bank enclosures. These risks posed a unique challenge in terms of fire suppression. The obvious choice was FirePro.

Fire Safety Equipment worked closely with McKay on the design for this vessel and survey requirements. FirePro was chosen as the preferred suppression technology due to its extensive testing and results in fighting Lithium-Ion battery fires.

Over the past few years, we have seen a rise in the demand for lithium-ion batteries as an energy source and storage device for various types of electric equipment. This type of battery may be an attractive option, thanks to its weight and mobility, but they also pose an increased fire hazard.

Conventional fire-extinguishing agents face a number of challenges when combatting a Lithium-ion battery fire. Claims are often made regarding the effectiveness of certain agents in fighting a lithium-based fire with no real evidence provided.

FirePro, in collaboration with the accredited certification body KIWA, has completed a thorough range of fire tests involving Lithium-ion batteries. The scope of these tests was to understand Lithium-ion fires as a result of thermal runaway and to evaluate the efficiency of FirePro in controlling and suppressing battery runaway fires.

The results of these tests indicate that FirePro – which comprises micro-sized potassium salts suspended in a blend of inert gases – suppresses the fire by inhibiting the combustion chemical chain reactions and inerting the explosive atmosphere created, thus preventing re-ignition. As a result of this action, the temperature falls below the critical point necessary to sustain the thermal runaway sequence.

“What has really contributed to the success of this project was the way that the whole team came together, bringing their individual areas of expertise to the table,” says Foote, an experienced composite boatbuilder, project manager and business owner. “What we have done has never been done before, and there is no doubt we had the right people onboard to make it happen.“

WEBBCo has worked closely with naval architecture and design consultants SSC Marine, who bring experience spanning workboat and military vessels, luxury powerboats and America’s Cup boats, to develop the best design fit, and ensure all areas of performance are considered.

The electric propulsion and power management system was custom developed and designed by electrotechnology company McKay, to suit the route and charging infrastructure, and is the first of its kind in the southern hemisphere. The charging rate was a significant consideration in the boat’s design, impacting areas such as hull size, battery weight and vessel displacement.

WEBBCo and East by West Ferries worked with independent EV consultants Retyna on the coordination of the landside charging infrastructure, including wharf strengthening requirements, supplier selection, and permissions.

Comprehensive sea trials are well underway, with the boat being put through her paces on the water before entering service later this year.

More info can be found at: www.electricboatbuilders.co.nz

Vessel – Vanguard

Finish: 2019

MacLab’s brand new purpose-built mussel harvesting vessel was designed and build in New Zealand by Q-West. Capable of carrying out two days worth of factory production on the water and able to harvest in all weather conditions that Golden Bay and Tasman Bay can present.

Fire Safety Equipment, together with Q-West was responsible for the implementation and installation of a FirePro Fire Suppression system to protect the engine room of the Vanguard.

FirePro was selected due to its ease of installation and superior list of marine certifications when compared to any other aerosol on the market.

Christchurch Justice & Emergency Services Precinct

Building area: 42,000 m²

Max. occupancy: 2000

Finish: Early-Mid 2017

The Christchurch Justice & Emergency Services Precinct (the Precinct) is a $300 million anchor project, led by the Ministry of Justice.

The Precinct brings together all justice and emergency services in one purpose-built, leading-edge precinct in central Christchurch. The Precinct made up of 3 buildings (the Justice Building, the Emergency Services Building and a car park for operational vehicles) is located in the central city block bordered by Colombo, Tuam, Durham and Lichfield Streets in Christchurch’s central business district. Its location will play a critical role in defining the southern edge of a more compact and vibrant city centre.

An estimated 2,000 people will work in or use the 42,000m2 Precinct daily. At the peak of construction, 500 to 600 people will be working onsite each day.

It is the largest multi-agency government co-location project in New Zealand’s history and the first major public building to be built in Christchurch by the government since the earthquakes of 2010 and 2011.

The Precinct will help restore confidence in Christchurch as a vibrant city of which its people can be proud. This is an important and exciting initiative for the people of Christchurch and all New Zealanders.

Fire Safety Equipment, together with Triangle Fire Protection was responsible for the implementation of a gaseous flood system to protect the ICT and Radio room of the precinct. FSE worked with our client and fire engineers to select the Ansul Sapphire Novec 1230 system as the most appropriate gaseous flood system for this environment.

The Ansul Sapphire system was selected due to being the agreed safest solution in the seismically active environment due to its reduced piping and cylinder footprint, lower pressure cylinders, and lower flood rate required to protect the environment.

FSE worked with all stakeholders and above supplying product, provided such services as design drawing, design verification, system hydraulic calculations, and room integrity testing/verification.

Vodafone Christchurch

Building area: 9,500 m²

Max. occupancy: 880

Finish: Sep 2016

The purpose-built, five-level facility at Tuam Street allowed Vodafone to bring together its current 450 Christchurch staff – working three existing sites – into one central location, with significant capacity for future expansion and growth.

Fire Safety Equipment, together with Fire Solutions was responsible for the implementation of a gaseous flood system to protect the communications room of the Vodafone facility. FSE worked with our client and fire engineers to select the Tyco’s iFlow IG-541 inert gas flood system as the most suitable for the environment.

The Tyco’s iFlow IG-541 inert gas flood system was selected due to being the agreed smartest solution to protect the enclosure. IG-541 was selected due to its high pressure and necessary location of the cylinder bank. LPG iFlow IG-541’s unique valve design also provided advantages in that a manifold was not required in this particular job. Reducing cost and install time for all concerned.

FSE worked with all stakeholders and above supplying product, provided such services as design drawing, design verification, system hydraulic calculations, and room integrity testing/verification.